Welcome to INDYGREEN TECHNOLOGIES

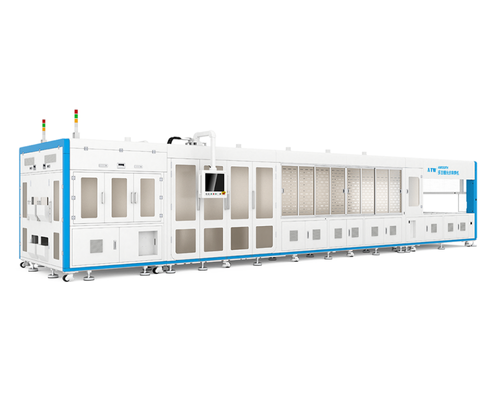

Tabber Stringers

Tabber Stringer

Our Tabber Stringer Machines are advanced, high-precision systems designed to interconnect solar cells with maximum accuracy and speed — forming the foundation of high-quality PV module production.These machines automatically solder solar cells using tinned copper ribbons or interconnects, creating perfectly aligned cell strings that ensure excellent electrical conductivity, mechanical stability, and superior module efficiency.

Whether you are operating a semi-automatic or fully automatic solar line, our tabber stringers guarantee precision soldering, high throughput, and minimal cell breakage, making them an essential component of every modern solar manufacturing facility.

| Technical Specifications (Typical Range) | |

|---|---|

| Throughput: | 1,200–2,800 cells/hour |

| Cell Size Compatibility: | 156–230 mm |

| Busbar Support: | 5BB-24BB ( For any cut cells 30mm-220mm) |

| Alignment Accuracy: | ±0.3 mm |

| Cell Breakage Rate: | ≤0.1% |

| Power Supply: | 380V / 50Hz |

| Operating Mode: | Automatic with PLC + HMI touch control |

| Data Interface: | MES / SCADA compatible |

Advantages

- High Productivity: Continuous automatic operation reduces production cycle time.

- Consistent Quality: Uniform soldering improves module reliability and efficiency.

- Reduced Manpower: Fully automatic handling minimizes operator dependency.

- Easy Maintenance: Quick-access design and diagnostic alerts for minimal downtime.

- Energy Efficient: Optimized heating systems reduce power consumption.

- Scalable Integration: Compatible with layup and bussing robots for fully automated lines.

Applications

- Solar PV Module Assembly Lines

- Cell Interconnection for R&D or Pilot Lines

- High-Speed Production Plants for Mono PERC, HJT, and TOPCon Modules

- Upgrades for Semi-Automatic and Fully Automatic PV Lines

Copyright © 2012 INDYGREEN TECHNOLOGIES | All Rights Reserved.

Get a Quote

Get a Quote