Welcome to INDYGREEN TECHNOLOGIES

Fully Auto Lines

Fully Auto Lines

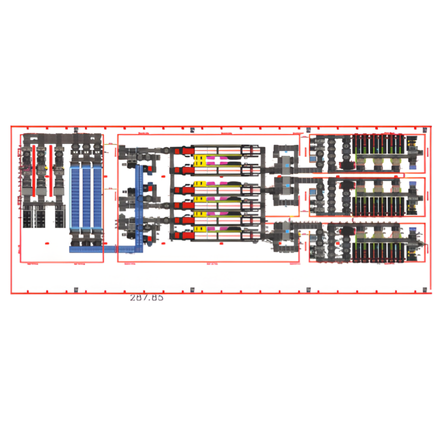

Our Fully Automatic Solar PV Module Production Lines represent the next generation of high-efficiency solar panel manufacturing technology, designed for large-scale production with maximum automation, precision, and reliability. These advanced lines ensure consistent quality, faster throughput, and minimal human intervention, delivering superior productivity for modern solar module factories.

Equipped with state-of-the-art robotics, intelligent conveyors, and AI-based process control, our fully automated systems streamline every stage of solar module assembly — from cell stringing to final testing — ensuring high yield, operational stability, and seamless performance around the clock.

Capacity

Complete Process Automation

Our fully automatic lines integrate the following key processes:

- Automatic Cell Loading, Tabber & Stringer Machines for precise cell interconnection

- Robotic Layup and Bussing Stations ensuring perfect alignment and minimal cell breakage

- Automatic Glass & Backsheet Loading Systems for uniform lamination preparation

- High-Precision Lamination Units with optimized thermal and vacuum profiles

- Automatic Trimming, Framing, and Junction Box Installation Machines

- Integrated EL, Hi-Pot, and IV Testing Systems for quality assurance

- Automatic Sorting, Packaging, and Data Traceability Modules

Each system is linked via smart conveyors and MES integration, allowing centralized control and real-time monitoring.

Key Advantages

High Production Capacity

Up to 100–300 MW per year depending on configuration.

Zero Manual Handling

Robotics and conveyors manage every step for consistent quality.

Precision & Repeatability

Maintains cell alignment and soldering accuracy with < 0.3 mm tolerance.

Reduced Labor Costs

Only minimal operators required for supervision and quality control.

Real-Time Monitoring

Smart sensors and MES connectivity enable predictive maintenance and data tracking.

Compatibility

Supports Mono PERC, TOPCon, HJT, Bifacial, and IBC module technologies.

Energy-Efficient Design

Optimized for low power consumption and high output ratio.

Applications

- Utility-scale solar module manufacturing plants

- Export-oriented PV factories

- High-efficiency module production for residential, commercial, and utility markets

- Upgradation of existing semi-automatic lines to full automation

Value-Added Services

- Complete turnkey project execution — from factory layout to installation

- Process optimization and technology transfer for module efficiency improvement

- On-site training, maintenance, and after-sales support

- Integration with ERP/MES systems for production data management and traceability

Benifits

Fully Automated

End-to-end automation from solar cell to finished module.

24/7 Continuous Operation

Designed for nonstop performance with minimal downtime.

Zero Human Error

Automation ensures precision, consistency, and maximum throughput.

High Output Speed

Shorter cycle time per module increases daily production efficiency.

Global Support Network

Worldwide access to spare parts and technical service for reliability.

Copyright © 2012 INDYGREEN TECHNOLOGIES | All Rights Reserved.

Get a Quote

Get a Quote