Welcome to INDYGREEN TECHNOLOGIES

BESS Container Assembly Lines

BESS Container Assembly Lines

The BESS (Battery Energy Storage System) container assembly line is an advanced automated production system designed for efficient and precise assembly of large-scale energy storage containers. It integrates processes such as module installation, busbar connection, wiring, cooling system integration, and final container assembly within a streamlined workflow. Utilizing robotic handling, smart inspection, and automated fastening systems, it ensures high productivity, safety, and consistency in every unit. The line’s modular and scalable design allows easy customization for various container capacities and configurations, making it ideal for manufacturing grid-scale and commercial energy storage solutions supporting renewable energy and power stabilization.

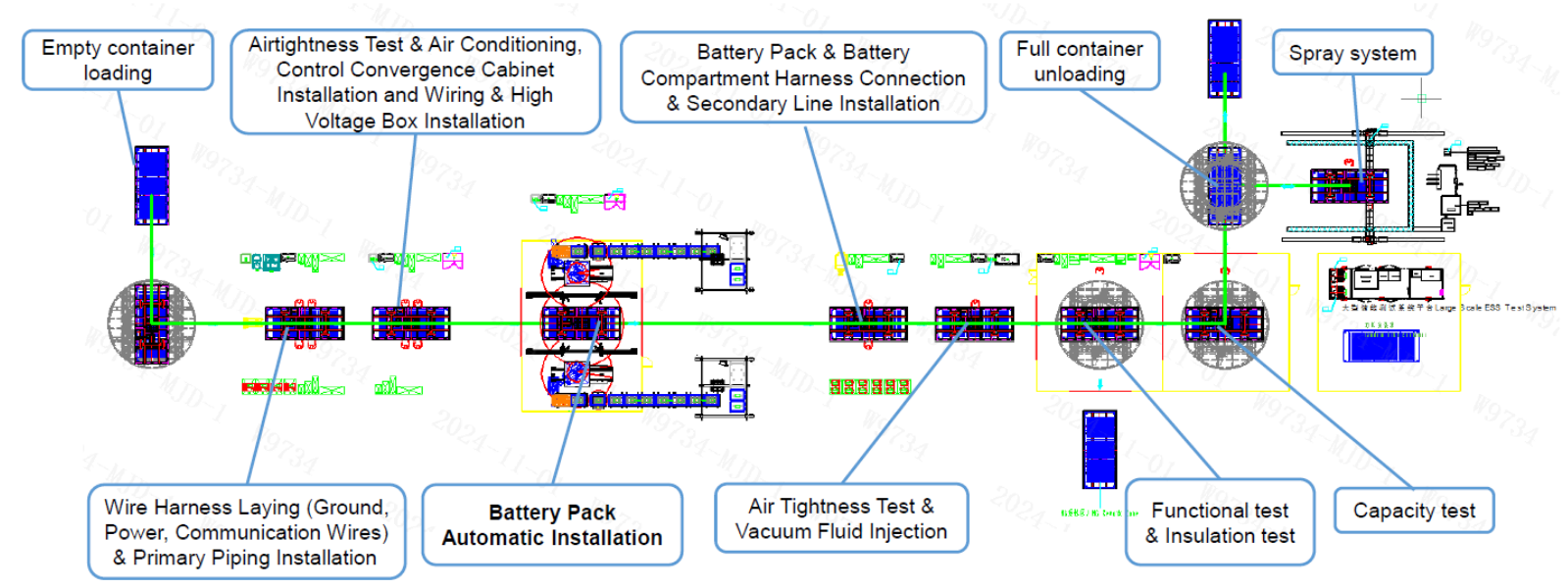

1. Automatic BESS Container Lines

- Production Line Size:100m(L)x 16m(W)x 6m(H)

- Container Transfer Method: Heavy load AGV Auto Transportation

- Pack Installation Method: Automatic Pack Insertion by Gantry System

- Required Ground Load Bearing Capacity:5000kg/m²

- Required Manpower:14persons (dynamic test station and spray system are not included)

AGV

Gantry System

Straddle

forklift

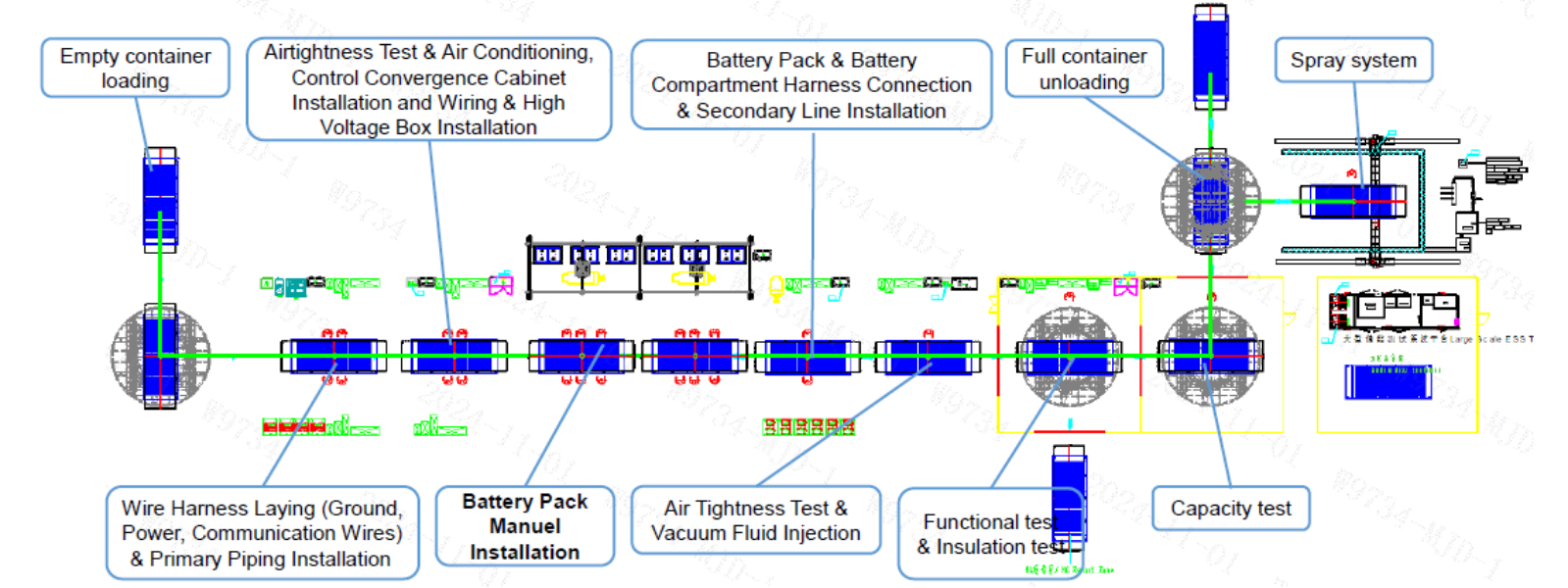

2. Manual BESS Container Lines

- Production Line Size:100m(L)x 16m(W)x 6m(H)

- Container Transfer Method: Heavy load AGV Auto Transportation/ RGV/ Electric Flatcar/ Straddle

- Pack Installation Method: Electric Lifting Forklift

- Requiredground load bearing capacity:5000kg/m²

- RequiredManpower:22 -28persons (dynamic test station and spray system are not included)

Copyright © 2012 INDYGREEN TECHNOLOGIES | All Rights Reserved.

Get a Quote

Get a Quote