Welcome to INDYGREEN TECHNOLOGIES

PV Reliability Turnkey Lab

Steady-state simulator

| Meet Standards: | IEC61215-2 MQT09 IEC61730-2 MST21 IEC61730-2 MST22 |

| Test purpose: | Determine the ability of the component to withstand the thermal spot thermal effect, and evaluate the welding melting or encapsulation degradation that may be caused by this effect. Battery failures, battery mismatches, shading or soiling can all cause such defects. |

Product Features:

- The equipment is equipped with the function of automatically adjusting the light intensity.

- The equipment uses Siemens PLC to ensure the long-term stable operation of the equipment.

- The equipment can be selected as walk-in type or drawer type to meet the customized needs of customers.

| Main Technical Parameters | |

|---|---|

| Box structure | Cold storage panel (insulation layer thickness: 100mm to 150mm) |

| Sample temperature range | 40℃ to 90℃ (non-standard customization is supported) |

| Temperature uniformity | ±2℃ |

| Sample temperature uniformity | ±4℃ |

| Light source drive | EPS |

| Light source category | Metal halide lamp |

| Light source power | 2KW / 4KW |

| Tube warranty | ≥2000 hours |

| Service life | ≥2500 hours |

| Spectral range | 300 – 1200nm |

| Light intensity range | 800 – 1300W/m² |

| Spectral grade | Class B (AM1.5) |

| Non-uniformity | Class B (≤ ±5%) |

| Instability | Class A (≤ ±2%) |

| Irradiance sensor | Imported brand |

| Cooling method | Air cooling / Water cooling |

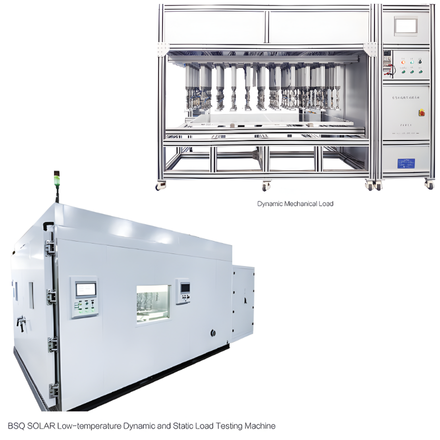

Dynamic and Static Load Testing Machine

Product Features:

- The control software simultaneously collects data including cylinder pressure, module surface pressure, module temperature, continuity current, module voltage, and deformation measurements.

- Featuring an intuitive HMI graphical interface with customizable current settings to meet diverse customer requirements.

- Supports visual data charts and Excel export formats for flexible data analysis needs.

- Power specifications: 60V 5A (customizable)

- Module mounting methods:Clamp mounting. Screw-hole mounting. Solar tracker mounting bracket installation.

- Equipped with dedicated load cells for periodic equipment verification (optional accessory).

Humidity-freeze chamber

Product Features:

- Energy conservation: The latest cooling capacity control technology of thermal expansion valve + capillary tube + cold output is adopted, which changes the traditional method of using a heater to offset the cooling capacity for controlling the temperature of the box. The power consumption is reduced to achieve energy-saving effect (40% more energy-efficient than the traditional method).

- Internet of Things: Both the environmental test chamber and the power supply system are manufactured by BSQ. The environmental test chamber can be connected to the extemal PID power supply and the environmental monitoring power supply system to form a local area network for online operation. (When the aging equipment malfunctions, the extemal PID equipment can be automatically and emergently stopped, reducing the risk of electric shock to personnel and ensuring the safety of samples, meeting the requirements of the latest PID test standards.)

| Meet Standards: | IEC61215-2 MQT11 , IEC61215-2 MQT12 , IEC61215-2 MQT13 , IEC61215-2 MQT21 , IEC61730-2 MST51 , IEC61730-2 MST52 , IEC61730-2 MST53 , IEC61730-2 MST55 , IEC61730-2 MST56 |

| Test purpose: | Determine the ability of the component to withstand the thermal spot thermal effect, and evaluate the welding melting or encapsulation degradation that may be caused by this effect. Battery failures, battery mismatches, shading or soiling can all cause such defects. Determine the ability of the component to withstand the effects of high temperature and high humidity, as well as subsequent sub - zero temperatures. Determine the ability of the component to withstand the effects of long - term moisture penetration. |

| Main Technical Parameters | |

|---|---|

| Temperature range | −50℃ ~ 150℃ |

| Temperature deviation | ≤ ±2.0℃ |

| Humidity fluctuation | ≤ ±1.0℃ |

| Temperature uniformity | ≤2℃ |

| Heating/cooling rate | 0.5~5℃/min (customizable) |

| Humidity range | 20%~98%R·H |

| Humidity deviation | ±2% (>75%RH); ±5% (≤75%RH) |

| Humidity fluctuation | ≤1.5%R·H |

| Humidity uniformity | ≤3%R·H |

| Humidity stabilization time | Within 15 minutes after the temperature stabilizes |

Copyright © 2012 INDYGREEN TECHNOLOGIES | All Rights Reserved.

Get a Quote

Get a Quote