Welcome to INDYGREEN TECHNOLOGIES

Giga Factories

Typical Production Flow for 1 GWh LFP Cell Line

Raw Material Preparation

- Cathode Material: LFP powder (LiFePO₄) mixed with conductive carbon and binder.

- Anode Material: Graphite (natural or synthetic) mixed with binder

- Slurry Mixing: High-speed mixers create uniform cathode and anode slurries.

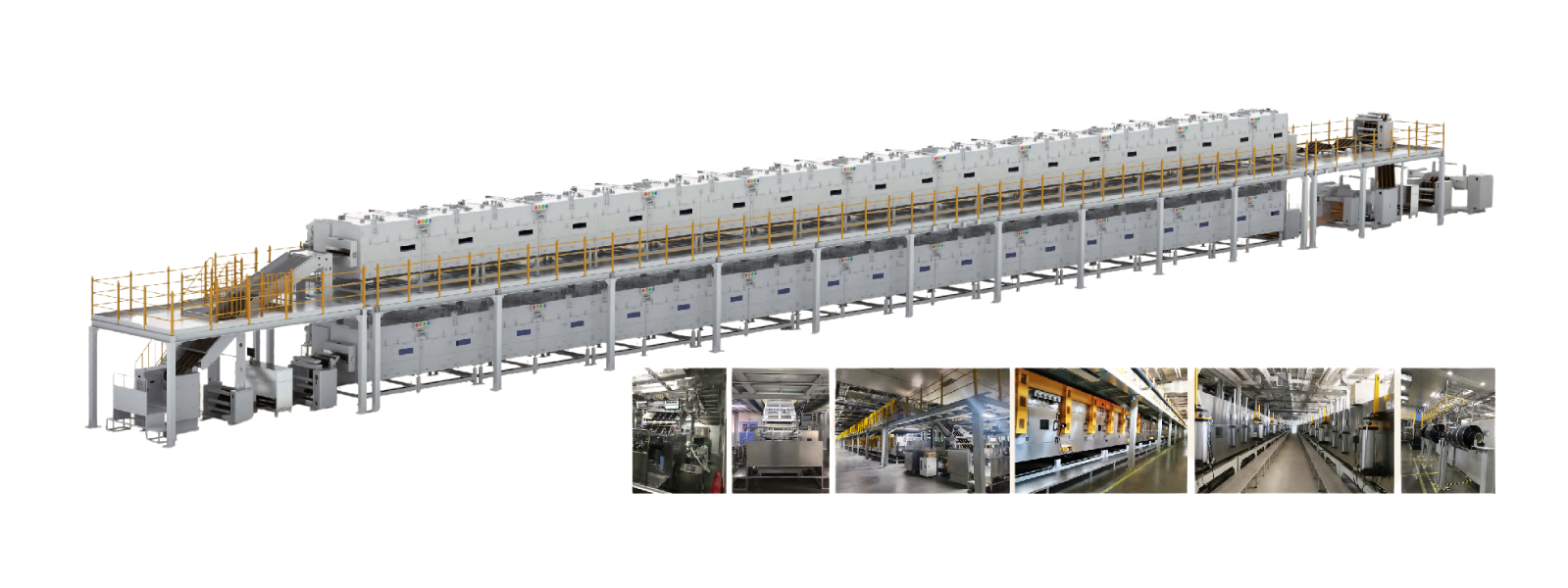

Electrode Manufacturing

- Coating: Slurries coated on aluminum (cathode) and copper (anode) foils.

- Drying: Continuous drying ovens remove solvents.

- Calendering: Rolls compress coated foils for uniform density and thickness.

- Slitting: Electrodes cut into precise widths for stacking or winding.

Cell Assembly

- Stacking / Winding: LFP cells can be prismatic or cylindrical, depending on design.

- Electrolyte Filling: Cells filled with LiPF₆-based electrolyte.

- Sealing: Pouch or prismatic cans sealed in controlled dry room conditions.

Formation & Aging

- Formation: Controlled charge-discharge cycles activate electrodes and form SEI layer.

- Aging: Cells rest for stability and performance verification.

- Testing & Grading: Cells sorted by voltage, capacity, and impedance.

Packing & Traceability

- PCells packed in vacuum-sealed trays under inert atmosphere.

- Data logged into MES (Manufacturing Execution System) for traceability.

Key Specifications for 1 GWh LFP Line

| Parameter | Specification |

|---|---|

| Annual Output | 1 GWh (~20 million 50 Ah cells) |

| Chemistry | Lithium Iron Phosphate (LiFePO₄) |

| Cell Format | Prismatic / Pouch |

| Production Area | ~20,000–25,000 m² (cleanroom zones) |

| Automation Level | Semi or fully automated line |

| Power Consumption | ~15–20 MW installed capacity |

| Workforce | 200–300 (operators + engineers) |

| Dry Room Humidity | < 1% RH (dew point −40°C) |

Copyright © 2012 INDYGREEN TECHNOLOGIES | All Rights Reserved.

Get a Quote

Get a Quote